LEDRig

Efficient UV Glass-Fibre Liner Curing

LEDRig devices are designed for curing glass fibre-reinforced polymer (GFRP) liners in sewer rehabilitation and manholes. Our patented cooling technology enhances LED efficiency, reducing both curing time and energy consumption compared to traditional UV lamps. With an automatic stop at the end of the cure, the light chain automatically stops upon reaching the end of the liner, making it easy for the user to control.

Enquire about this product

UV LED Advantages

Smart Radiation Modules: Maximizes energy efficiency, minimizes heat, and reduces the size of the power supply unit.

Instant On/Off: No ignition spacing required; all modules activate simultaneously, saving time.

Safe Handling: UV LED modules stay cool, allowing immediate removal after curing.

Specification

Dimensions

1121 x 833 x 1515 cm

Total Weight

225 KG

Material

Chassis based on stainless steel, aluminium, ABS

Working Diameters

DN150 - DN800

PORTABLE

200m cable length for flexible on-site operations.

MAINLINES & LATERALS

For DN150 to DN600 pull-in glass-fibre liners.

EFFICIENT

Reduced electrical power needs and costs for ancillary equipment.

COMATIABLE

Works with GRP UV liners and our Spectra Dive for manhole rehab.

Enhanced Curing Efficiency

- Quick Setup: No ignition spacing.

- Optimised Speed: Faster curing times.

- Safe Operation: No risk from hot components.

- Portable Power: Compact, light, one-phase inverter generator.

- Timesaving: Streamlined job site processes.

Modular and Adaptable Design

Design: Portable & compact system that can fit in a small van of up to 3.5 ton and its mobility allows for access to difficult to reach places.Compatible with mainline pipes and manhole renovation.

Versatile: Suitable for curing of GRP liner from DN 150 to DN 800, adjustable to various pipe sizes.

On-Line Reporting

LEDRig’s online reporting feature records all data from each job. Easily accessible via PC or handheld devices, it generates customisable reports with key details like contractor, client, project name, curing parameters, and more. Final reports can be saved as PDFs for easy sharing and record-keeping.

The LEDRig is constantly recording data – such as time, pressure, speed of cure, temperature of the LEDs, air, and liner, and distance cured. This data on the calibration and cure of the liner is available in graphs in a report at the end of the cure.

Patented Cooling Technology

Active cooling technology that contributes to LED modules’ extremely low working temperatures. LEDRig works together with an air compressor and an air cooler-dryer that help to keep the liner during the curing process and contributes to cool down and dry the air running through the LED modules

Curing Speeds

LEDRig offers optimal curing speeds based on liner diameter and thickness, providing versatile and efficient performance for various job site conditions.

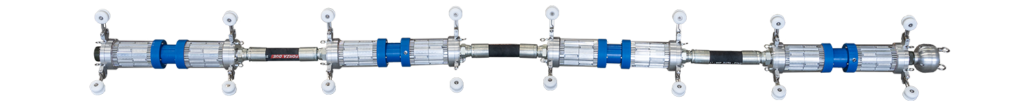

Curing Heads

With a 2.5m LED chain, the LEDRig has power of 2400W. It is an eco-friendly system with low consumption of electricity and one phase only of approximately 3320W, 15 A/220V or 30A/110V. Multiple sensors enable full curing control along with front & back cameras on the LED light train give visual control. 2 IR sensors spaced throughout the LED light train provide real-time temperature data and control. With an automatic stop at the end of the cure, the light chain automatically stops upon reaching the end of the liner, making it easy for the user to control.

Spectra Dive - L2400

With the specialized SpectraDive 2400W head, you can easily cure manholes with your LEDRig. With manhole rehabilitation you can to cure thicker manhole liners.

KEEP IN TOUCH

Subscribe to our Newsletter

Fill out your details below to confirm you opted in to receive important updates, free resources and more via email from Sewertronics and Minicam Group. By doing so, you are confirming your subscription to the Sewertronics Newsletter.

You can always withdraw your consent or unsubscribe from our newsletter.